China’s aluminum profile industry has been thriving since the reform and opening up, and aluminum profiles, as important application materials in the construction and machinery industries, have made China the world’s largest production base and consumer market for aluminum profiles.

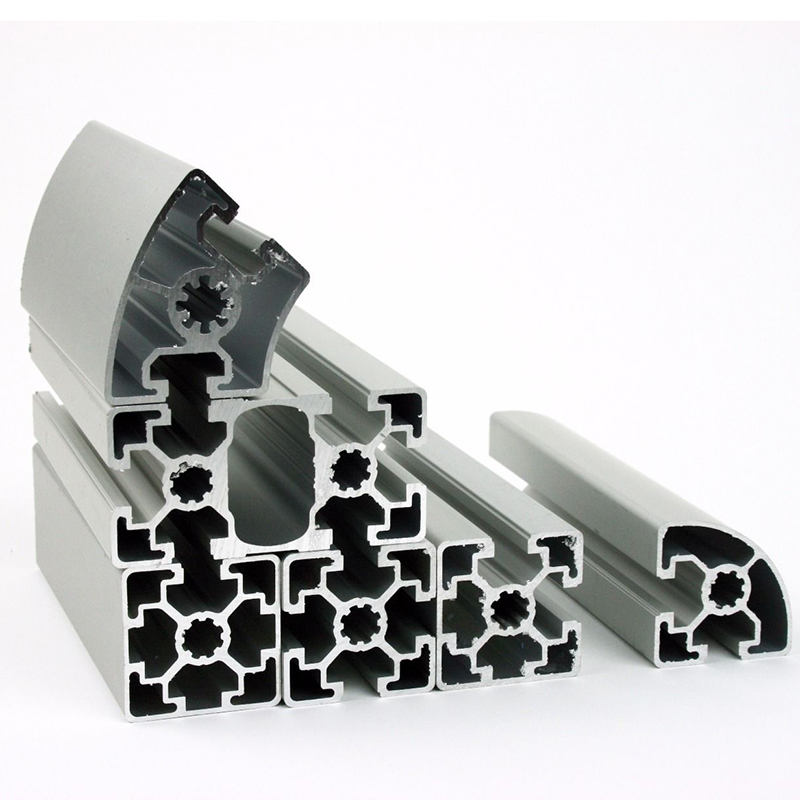

As is well known, as downstream processed products of the aluminum industry chain, aluminum profiles mainly purchase raw materials such as aluminum bars and electrolytic aluminum. The production process of aluminum bars, which are obtained by hot melting and extrusion into aluminum materials with different cross-sectional shapes, is also continuously improving. Aluminum profiles are widely used in various modern industries.

Aluminum profiles can be divided into two types according to their use:

Building aluminum profiles, mainly used in the construction field, such as doors, windows, and curtain wall materials.

Industrial aluminum profiles, mainly used in aerospace, rail transit, mechanical equipment, electronic products, and general industrial aluminum profiles.

Aluminum profiles can be divided into several types according to their surface treatment:

Anodized and colored profiles

Electrophoretic painted profiles

Powder coated profiles

Fluorocarbon painted profiles

Polished profiles

Wood grain profiles

Aluminum-wood composite profiles

Aluminum profiles can also be classified according to their composition content:

The aluminum profiles are classified into series 1-9 based on the different aluminum content and the different alloying elements added.

The 1xxx series represents pure aluminum, with a purity of over 99.00%, and is the series with the highest aluminum content.

The 2xxx series represents aluminum-copper alloys, with a copper element content of about 3-5%. It is mainly used in the aviation industry and is not commonly used in conventional industry.

The 3xxx series represents aluminum-manganese alloys, with a manganese element content of 1.0-1.5%. It is mainly used as an anti-rust aluminum plate.

The 4xxx series represents aluminum-silicon alloys, with a silicon element content of 4.5-6.0%. It is commonly used as building materials, mechanical parts, forging materials, welding materials, with low melting point and good corrosion resistance.

The 5xxx series represents aluminum-magnesium alloys, with a magnesium element content of 3-5%. It is one of the more mature aluminum plate series in China.

The 6xxx series represents aluminum-magnesium-silicon alloys, with high strength, easy coating, and good corrosion resistance. It is currently one of the most frequently used products in the market.

The 7xxx series represents aluminum-zinc alloys, mainly used in the aviation industry for the manufacture of high-stress structural parts and molds with high strength and corrosion resistance.

The 8xxx series is mainly represented by 8011, which is mainly used for bottle caps and radiators. Most of them are used as aluminum foil, and are less commonly used.

The 9xxx series is a backup series, specifically designed to cope with aluminum plates containing other alloying elements.

According to the “Development Plan for Nonferrous Metal Industry (2016-2020)” compiled and released by the Ministry of Industry and Information Technology of China, China’s nonferrous metal industry will continue to develop, with a focus on improving the quality of aluminum profiles and promoting technological innovation.